In an era where technology TO And automation is coming into play in the manufacturing industry. The change is not just about robots replacing humans, but about developing a smart and safe human-machine collaboration model. This article will give you an overview of the application of AI in industrial settings. The actual application and impact on labor in the manufacturing sector is based on research and real examples from MIT and leading companies in the United States.

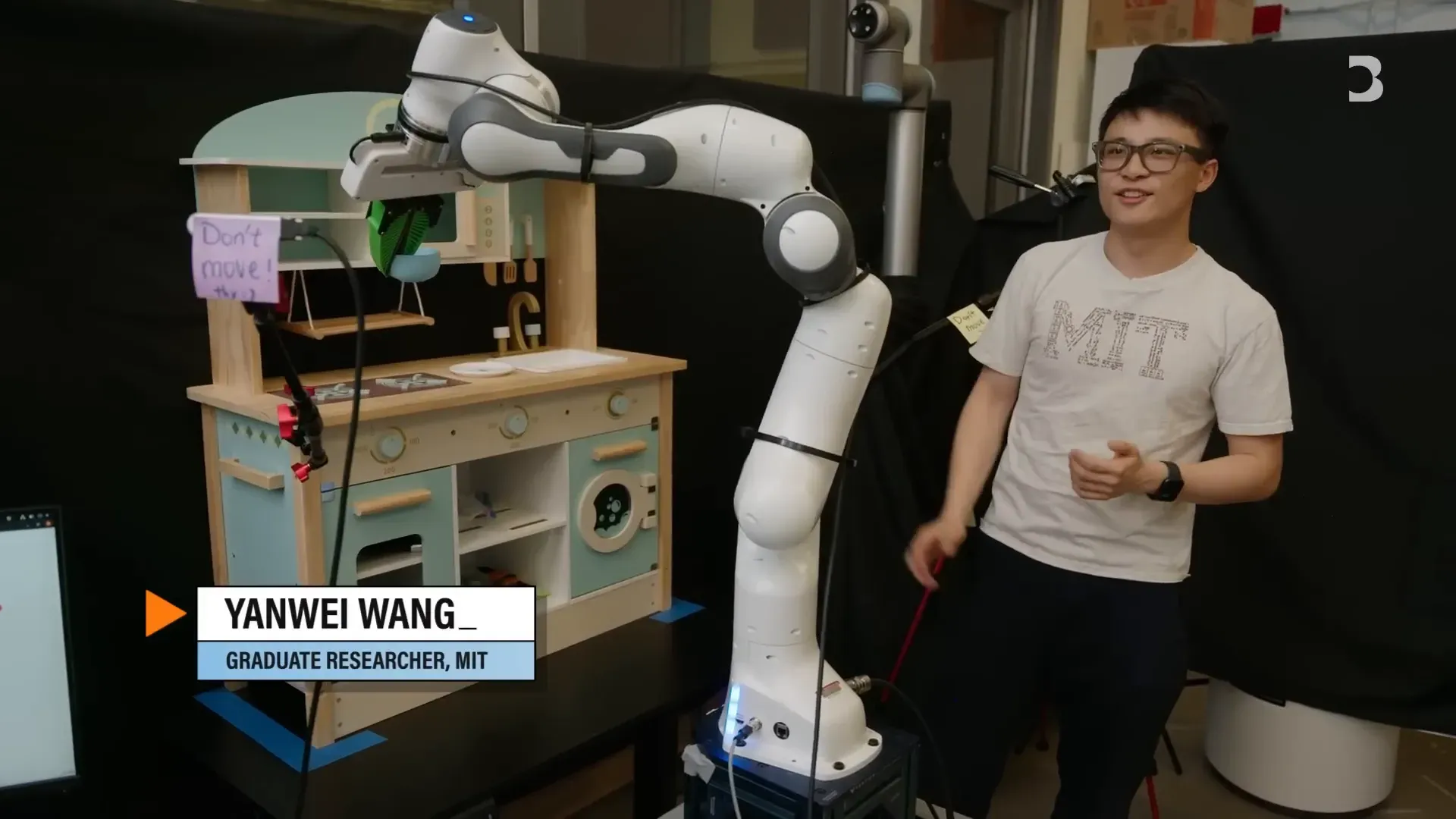

Robotics in the MIT Lab and Human Learning

at the Interactive Robotics Group Lab within the Massachusetts Institute of Technology ( MIT Engineers are developing robotic arms that seem to perform simple tasks such as catching balls and placing them in the sink, but in reality, these tasks are much more complicated than it seems. Robots are not only programmed to perform straightforward commands, but also to use TO This will help robots recognize human commands intelligently and safely, as well as predict their next steps.

This process of training robots is like teaching sports skills. If the robot is not working perfectly, the user can "massage" or adjust the posture correctly. The robot then automatically resumes the task until it completes. This is an example of collaboration between humans and robots, where humans provide high-level guidance. The robot handles low-level details on its own.

The Future of Factories: Human-Robot Collaboration

The factory concept of the future does not mean that it will be completely replaced by robots, but it will be a space where humans and robots work together in a balanced way. Researcher Ben Armstrong from MIT studied the effects of TO and automation to the American manufacturing sector. It has been found that these technologies have developed and spread more slowly than many people expected, and the impact on the workforce is usually gradual. It does not cause rapid or severe displacement of workers.

In the past, such as in the 1980s, General Motors tried to build a factory automation so perfect that it could turn off the lights in the factory. However, it fails due to robots malfunctioning, such as robots painting each other instead of cars, or incorrectly assembling car parts.

The current state of robots in American and Asian factories

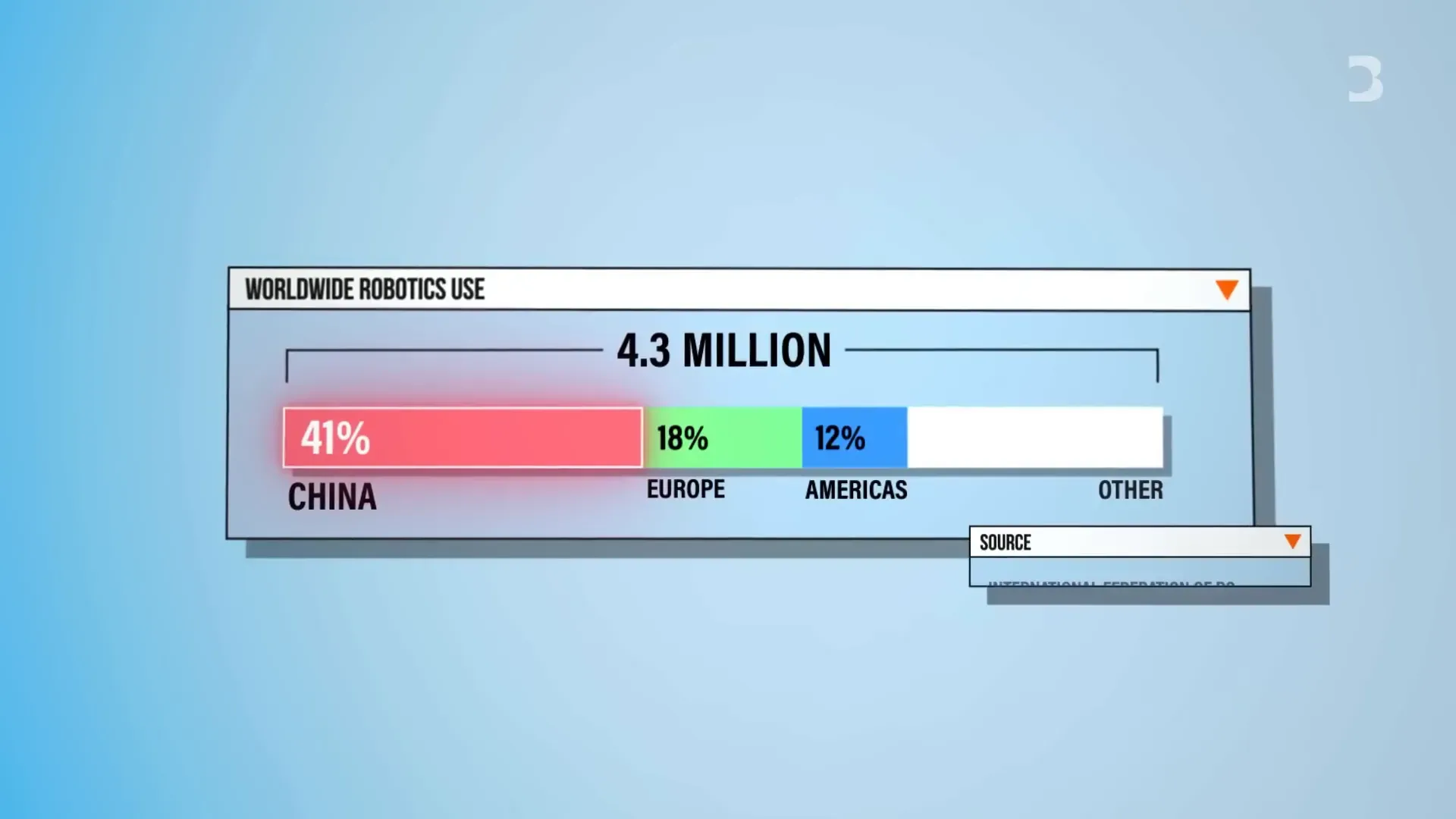

Despite the widespread use of robotics and automation, in 2021, only 12% of U.S. factories used at least one robot. Meanwhile, Asian countries, especially China, More than 40% of the world's robots are used in factories.

AI and Predictive Maintenance

TO It is not only used to control robots. But it also helps with machine maintenance tasks, such as at the Fiberon plant in North Carolina. Augury's AI equipment is used to detect and predict machine breakdowns in advance, reducing unplanned downtime and maintenance costs.

Augury's device uses sensors to detect the vibration, temperature, and magnetic field of the motor. TO Complex such as neural networks ( Deep Neural Networks ), Supplementary Learning ( Reinforcement Learning ) and models Transformer To analyze the problem and recommend an accurate solution.

Examples of AI in action in maintenance

It is easy to compare like when driving and hearing the sound of a fan belt making a warning sound, that is a sign that it needs to be checked or replaced. TO In the factory, it performs a similar function, remembering the different malfunction patterns of each machine to alert the technician team before major damage occurs.

AI vs. Factory Workers: Create Jobs or Replace?

One of the most frequently asked questions is, will AI replace the workforce? The CEO of Augury sees AI as a tool that empowers humans, not a substitute for humans. Rather, it reduces the workload of having to inspect every machine, allowing humans to focus on machines that really need attention.

While many companies are trying to bring in automation to reduce the number of employees, the truth is that the adoption of AI is often a modification of job roles and adds more complexity to the task. Workers must develop new skills to be able to work with rapidly changing technologies.

Challenges of the Manufacturing Sector in the Age of AI

- Constantly changing consumer needs

- Geopolitical tensions and supply chain issues

- Aging workforce and shortage of skilled workers

In particular, labor shortages are one of the biggest challenges facing the manufacturing sector today, and AI is seen as part of the solution that allows factories to continue operating even with fewer workers.

The Impact of AI on Factory Employment

According to a 2023 World Economic Forum survey, 41% of businesses worldwide expect to reduce headcount by 2030 due to the adoption of AI. However, this effect does not mean the disappearance of all jobs, but rather a change in the style of work and the skills required.

AI can detect manufacturing defects more accurately. This makes the product quality better, but there is a chance that some job positions will be replaced. However, most companies still need to find new jobs or train employees to meet new needs as they arise.

Job losses in the American manufacturing industry: what are the causes?

Over the past 45 years, the manufacturing industry in the United States has experienced a significant loss of jobs, which is caused by a variety of factors. Whether it's the relocation of production bases abroad (offshoring), fierce competition, and the adoption of automation technology, even in factories that use more robots. Sometimes, the number of machinists increases because they need people to control and maintain these machines.

The main thing is to question what the goals of the manufacturing industry should be. We want factories to be a source of mass jobs like they were in the post-World War II era, or to focus on high-quality jobs where workers feel satisfied and become more skilled.

Human-robot relationship in factories

Proponents of automation often see robots as better than humans because they do not take breaks and do not make mistakes. Humans can observe and resolve complex situations better than machines in many cases, so it is still necessary to have humans in control and work with AI.

Despite the development of AI models that can learn and improve themselves, "Humans in the loop" are still an important part of how systems work efficiently and safely.

Technical terms you should know

- AI (Artificial Intelligence) : Artificial intelligence is a computer system that can perform tasks that require thinking, such as learning, planning, and problem-solving.

- Deep Neural Networks : Deep neural networks are AI models that mimic the structure of the human brain. It is used for pattern recognition and processing of large amounts of data.

- Reinforcement Learning : Reinforcement learning is an AI training technique by providing rewards or penalties to allow the system to learn how to make the best decisions.

- Transformer : AI models used in natural language processing and deep learning. Highly effective in understanding complex data.

- Predictive Maintenance : Predictive Maintenance It uses AI to analyze data from sensors to predict machine damage in advance.

Conclusion from Insiderly

The adoption of AI and automation in factories is not just about replacing human labor, but about changing the way we work and creating more quality jobs. Despite concerns about future job losses, seeing AI as a tool to empower humans will help to achieve a better balance between technology and labor.

The success of AI in factories depends not only on technology, but also on the design of systems that allow humans and robots to work together safely and efficiently. In addition, skill development and training of workers to be ready for new technologies are the key to the sustainable growth of the manufacturing industry in the future.

From the perspective of AI experts, seeing AI as a partner, not an enemy of the workforce, will help lead to the design of user-friendly systems and reduce the risk of mass unemployment that can occur if AI is used carelessly. Cooperation between the government Therefore, businesses and workers are needed to prepare for this major change.

Frequently Asked Questions (FAQ)

Will AI replace all factory jobs?

AI is not replacing all jobs, but it will change the role of workers to work with machines more efficiently. Some types of jobs may disappear, but new jobs that require higher skills will take their place.

What is Predictive Maintenance?

It uses AI to analyze data from sensors installed on machines. To predict and warn in advance that the machine may be damaged. Reduce unscheduled downtime and maintenance costs

Why do factories in China use more robots than America?

China invests heavily in automation and robotics in factories to increase efficiency and reduce costs. Meanwhile, the United States still uses a smaller proportion of robots due to different labor and investment structures.

How will robots and humans work together in a modern factory?

Humans will give a high level of guidance or control. The robot handles complex detailed tasks safely and efficiently. This synergy improves production speed and accuracy.

What skills should workers develop to support AI in factories?

Emphasis should be placed on the skills of controlling and maintaining automated machines. Data analysis and use of digital tools, including problem-solving skills and collaboration with AI.